26 Gauge Metal Roofing

- Kunal Singh

Are you tired of regularly repairing or replacing your torn roof because of heavy snow, hail storms, or heavy winds? Installing a 26-gauge metal roof to your pole barn shed, shop or living quarters promises long-lasting, cost-effective, durable, and sturdy roofing.

Shop the best quality 26 Guage roofing material with us. Steel and Stud is US’s one of the biggest manufacturers of metal buildings and roofing materials for commercial buildings and residential roofing. We supply corrugated metal roofing panels in all 22, 24, 26, and 26, 29 gauges, But if you are looking for a standing seam metal roof, the standard thickness of panels will be 22 and 24 gauges.

To have a clearer understanding of what a gauge is, the difference between 26 and 29 gauges, and when to buy thicker panels —keep reading; it will just take 2 min of your time but can help you save 20% of your spending.

Table of Contents

What is A Metal Roof Gauge?

The thickness of the metal panels used for roofing is referred to as a gauge. There are multiple options of metal roof panels and metal siding panels available in the market.

Guage is one of the parameters that help you in buying roofs and other materials for your metal building. The thinner the density, the higher the metal roof gauge number. The thickest metal roofs are 22 gauge, while the thinnest are 29 gauge. The numbers here are based on a weight of 41.82 pounds per square foot per inch of thickness.

Although thicker gauges are expensive, they are more robust to sustain extreme weather conditions. Thinner gauges are cheaper, but you cannot use them in places with heavy snow, rain, or high winds. Most homeowners in the US favor thinner gauges; thicker gauges are popular in states that frequently encounter bad weather.

You can check the Metal sheet Guage chart to find out how thick will be the roof sheet in other metals.

29 vs. 26 Gauge Metal Roofing

The two most common metal roof gauges are 26 and 29, both appropriate for residential metal roofing installation and commercial application. Both metal gauge types are fire-resistant and anti-rust corrosion. But choosing the correct gauge for your new metal roof depends on the kind of metal building, location, the wall and side panels gauge, and personal style. The main factors that differentiate 26 gauge from 29 gauge include:

Thickness

The 26 gauges can withstand more intense natural calamities since they are thicker than the 29 gauges. 26 gauge metal roofing thickness in mm is 0.45 mm, while the 29 metal gauge thickness is 0.34mm. We can determine the thickness from the 26 gauge metal roofing gauge conversion chart.

Durability

Water leaking is possible if you employ 26 gauge metal roofs in an area where it snows frequently. Because the metal is so thin, regular strong winds could also cause dent your roof or blow away portions of it.

Appearance

Metal roofs made of 26-gauge and 29-gauge are hard to differentiate in appearance. One cannot simply tell the metal gauge by glancing at the roofs. The gauge’s appearance will depend on the materials used to make it.

Waves and bumps in the metal sheet—known as oil canning—occur during installation if the installers do not precisely tighten the screws. Compared to 26-gauge metals, oil canning is more noticeable in 29-gauge metals.

Lifespan

.A 26-gauge metal roof’s thicker material won’t corrode or rust readily. These metal building ideas can quickly shed ice and snow and resist more than 14 mph winds. A 26-gauge metal roof can last for more than fifty years. These are mainly used for residential metal roofing. A 29-gauge metal only lasts 20 to 25 years since it is made of extremely thin metal.

Weight

A 26 Gauge Metal Roofing weight per foot is 12 ounces, while a 29 Gauge metal roofing weight per foot is 9 ounces.

Purlin Spacing

The purlin spacing for 26-gauge metal roofing is 4.5 feet. For 29-gauge metal roofing, the purlin spacing is about 2 feet.

Cost

The average cost of 26 gauge metal roofing is $1.75 to $4 per square foot, while 20 gauge metal roofing costs around $1.75 to $3 per square foot.

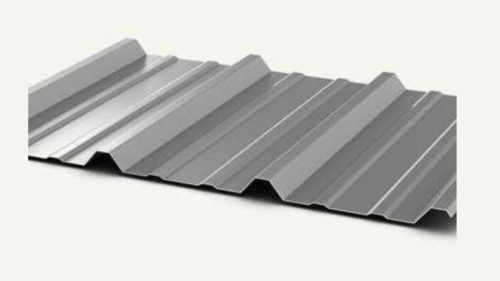

26 Gauge Metal Roofing Panels

Steel and Stud’s 26 gauge metal roofing panels are best for standard roofs, vertical roofs, and boxed eave roofs. To enhance longevity, we apply PAC-CLAD PVDF coating on prefinished sheet metal. It is used on roof panels made of steel and aluminum for sustainability in harsh settings.

Types of Metal Panels

The three metal roofing panels, Roof panels, and roofing panels.

Technical support with roofing systems is available from our qualified metal roofing staff. Our nationwide network of architectural representatives offers local assistance. One of the leading providers of commercial metal roofing, Steel and Stud are ready to help with material selection, finish specifications, and financial planning. We welcome your questions.

Different types of 26 gauge metal roofing colors increase its look and aesthetic value when someone watches it from the outside.

How to Install 26 Gauge Metal Roofing

Before metal roofing installation, it is important to know how to cut 26 gauge metal roofing with proper size. To install the 26 gauge metal roofing, we have to follow the below steps

Apply the underlayment

Keeping the underlayment flat and wrinkle-free during installation is challenging. As you unroll the underlayment across the roof, remove the adhesive backing’s bottom half. Layers should be placed six to eight inches apart.

Cut the underlayment flush once it has been rolled out and remove the remaining adhesive backing from underneath.

Order Panels To Fit

Keep your roof’s seams as seamless as possible. They don’t look fantastic, and they can allow water to enter behind the panels. I had the length of our roof adjusted for the metal roofing panels. They needed to be delivered on a flatbed trailer because they were almost 32 feet long. Of course, a big lift will be required to move the panels onto the roof. You’ll have to order shorter lengths if you don’t have one.

Bend Trim end closed

Cut and bend the leading end of the trim to wrap it around the corner before you install it. To connect to a wall, a corner, or end a space left by the trim, fold the tabs with a hand seamer. Each trim has a definite shape that calls for proper cuts and bends.

Splice And Overlap Trims

You will sew the ends of the trim together where they meet. First, angle-cut the underlapping trim’s bottom hem. Apply sealant on top after putting in the underlapping trim. Try opening the bottom hem to slide the lower part of the overlapping trim over the underlapping trim’s angle-cut hem.

Set the Panels

Place a foam sealing strip inside each metal panel. These strips prevent insects and water from entering the panel’s corrugated bottom by being designed to fit that surface. With butyl tape, attach the closing strips to the panels along the eave at a distance of about an inch from the edge. Also, ensure a 2” space between two 26 gauge metal roofing gaps.

Drive Screws Just Right

The secret to a watertight roof is to fasten the panels properly. Beginning at the bottom, fasten the panel in rows of screws as you work toward the ridge. Only tighten until the rubber gasket is compressed to the end part of the screw head, not past it. Before tightening the screws, check whether it’s a 26-gauge galvanized metal roofing to avoid rust.

Overlap The Panels

The metal panels have two distinct edges. When laid flat, the edge overlaps have a smaller rib leg that doesn’t touch the roof surface. Drainage is made into the rib on the underlapped side to keep water flowing toward the eave.

Cover The Rake Edge

It’s time to join the gable trim after securing the panels. This neatens the 26 gauge metal roofing edge and prevents snow and rain from entering the siding and roof panels. Apply butyl tape below the trim after bending the end to fit the corner at the eave.

Frequently Asked Questions

The thickness of the 26 gauge metal roofing can be determined from the 26 gauge metal roofing gauge chart. The average thickness is 0.45 mm. There will be many 26 gauge metal roofing for sale in steel and stud.

26 gauge metal roofing is very durable and can tolerate wind up to 150 mph. It also requires less maintenance. You can see various designs of 26 gauge metal from the steel and stud website.

In general, a 26-gauge metal roofing l is thicker than a 29-gauge. For this reason, it’s suitable to resist a strong breeze. A 26 gauge metal roofing price starts from $1.75 per square foot to $3 per square foot. You can check its price from steel and stud.

When securing a roof, the durability of the metal panel is a key element in stopping large-sized hailstorms. Steel and Stud advise a minimum of a 26 gauge steel roofing panel to withstand a strong hail storm.

Indoor Riding Arenas: Types, Features, Benefits, and Cost

Different Types of Metal Roofing for Commercial and Residential Buildings

What Is A Purlin? Types, Sizes, Designs, Accessories & Cost