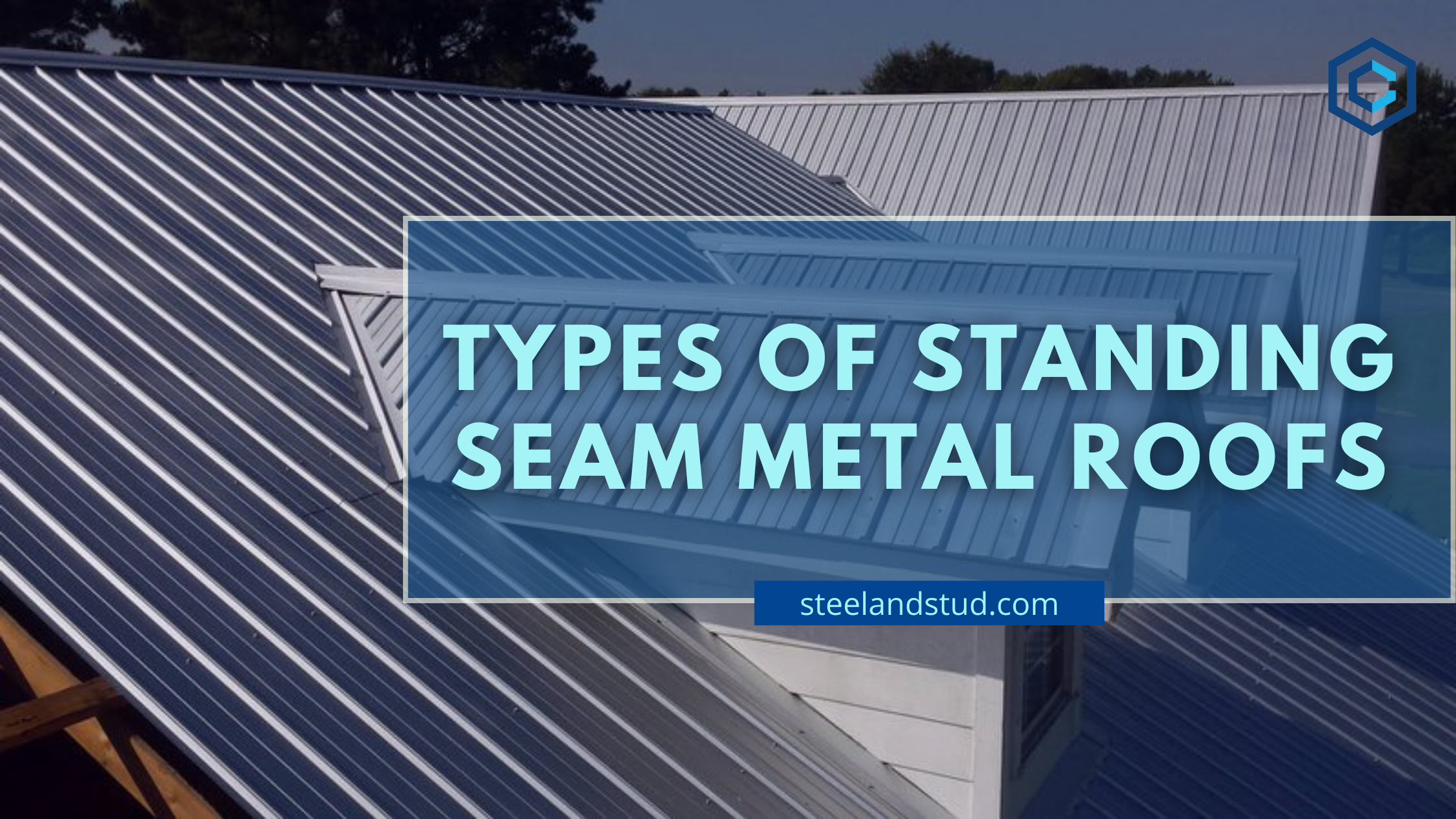

Types of Standing Seam Metal Roofs

- Kunal Singh

The product selection from types of standing seam metal roofs can seem daunting with so many panel variations. Standing seam panel types are distinguished by how they are engaged with each other and how they are laid on the roofing surface. The mechanism of attachment, engagement, designs and styles affect the initial cost and maintenance cost. With an appropriate choice of roof, you can save time, effort, and money for yourself.

Different types of standing seam metal roofs comprise metal panels and metal sheets that have been prefabricated or formed on site. Steel and Stud offer standing seam panels in different colors, gauges, and heights in your area.

Table of Contents

Standing Seam Roofs Available With Us

Standing seam metal roofing has vertical legs or elevated seams that protrude above the panel’s smooth and flat surface. Choose standing seam metal roofs over corrugated metal panels if the weather condition is severe in your region or you have a low slope roof. The standing seam gives a smooth seamless look to your roofing system with no barriers to block rainwater, snow, and debris and accumulate there.

There are several ways to attach a standing seam metal roof, but the two most popular types are clipped and fastening flange. Purlins also help in strengthening your metal roof.

Nail Fastening Flange

Also referred as nail strip panels, these panels are directly fastened to the roof deck with a fastener through a slotted flange. As metal roofs become hotter, the slotted flange limits the panels’ ability to expand and contract to around 45′. The most significant places for installing these exposed fastener systems are residences and other small, light commercial structures.

- Cheapest standing seam with exposed fastener panels

- Professional installers must fasten the screws properly to avoid any restriction movement.

- The metal close to the fastener head could rend due to ongoing expansion and contraction.

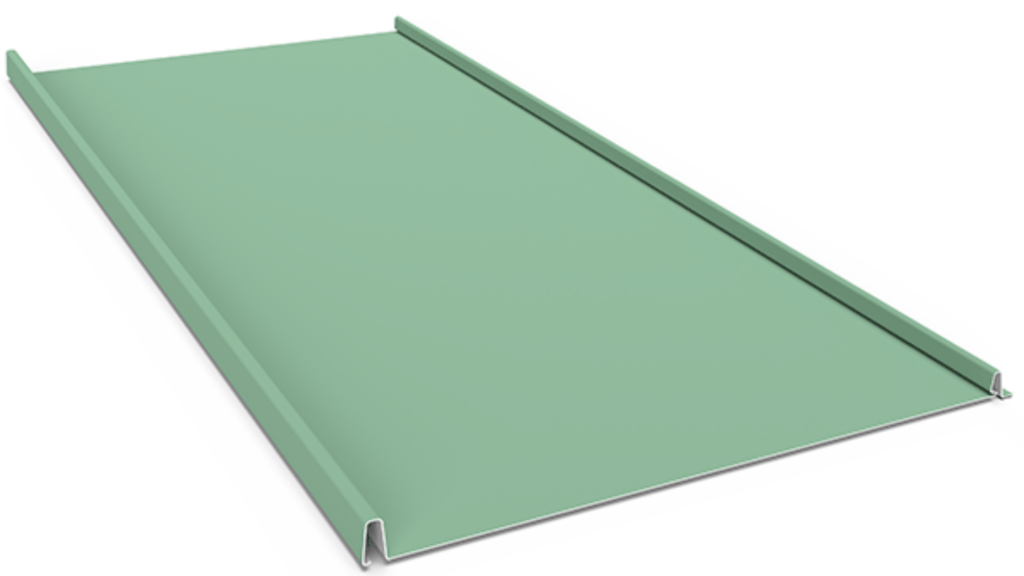

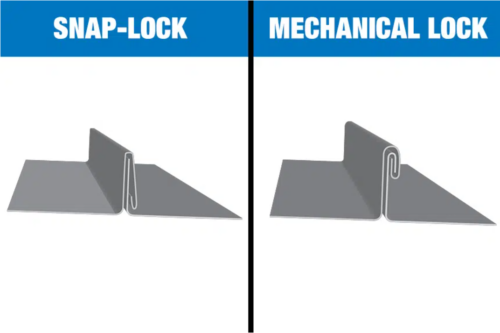

Clipped Snap lock

Clipped systems latch to the substructure using a heavy gauge steel clip incorporated with the male and female leg on the panel instead of nail-type panels that use flanges. In snap lock panels, the vertical legs are fitted over one another during installation, and the upper part is pushed down into the lower part until the legs correctly join.

- No extra tools are required during installation.

- The installation process is precise and more affordable.

- Concealed fasteners save the cost of rubber sealing washers, which often need to be replaced due to ongoing expansion and contraction.

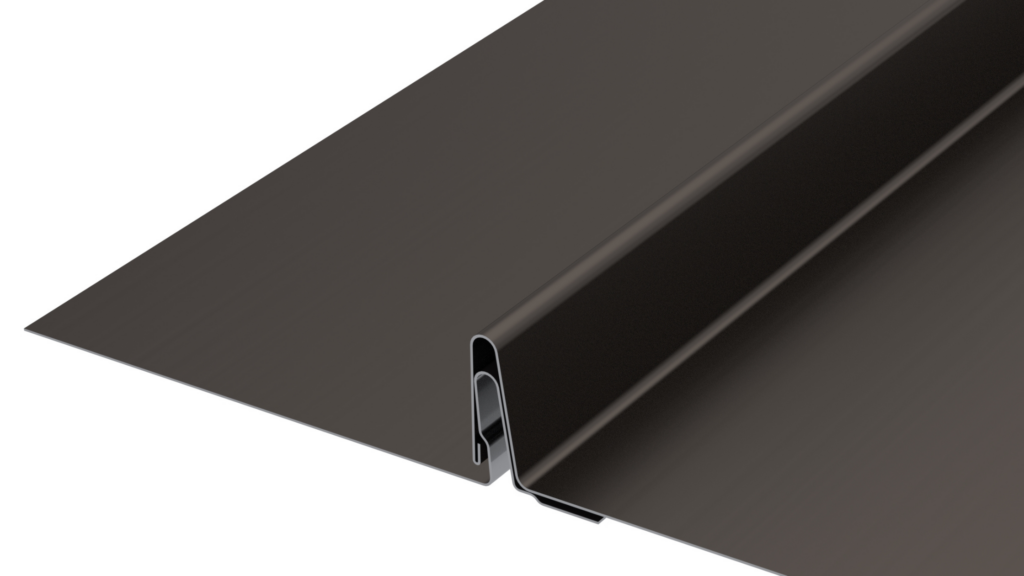

Mechanically Seamed

In contrast to snapped panels, mechanically seamed panels require using motorized seaming equipment for installation and engagement. The mechanical seam profile comprises panels with roll-formed edges that align with one another. The clip is attached to the male leg using the same screws used in the snap-lock profile. The edges can be bent manually or mechanically once the panels are connected.

There are two types of mechanical seams:

- Single lock

- Double lock

The panel seams are folded twice, once in a single lock and twice in a double lock.

- Most expensive standing seam metal roofs

- Require expertise, professional help, and tools.

- Most weather-tight.

Standing seam metal roof advantages and disadvantages

The main benefit of employing a standing Seam roof is its endurance, which outweighs its aesthetics and the potential cooling effect it may have on your property. These roofs are made to last; therefore, neither do they rust nor do most of them fade in the sun. The installation is this type of roof’s major drawback. Fewer roofers understand metal roof installation and metal roof materials, while the majority of roofers work with asphalt roofs. This indicates that it can be more challenging to locate someone informed about the type of roof.

Designs In Standing Seam Metal Roof

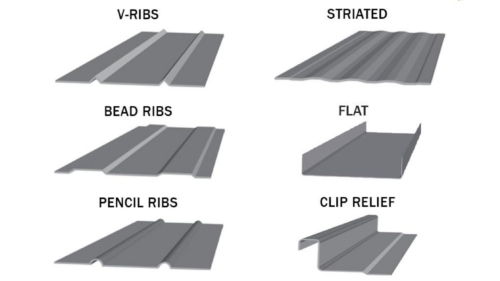

The plain flat or tapered or curved panels create different types of standing seam metal roofs for residential houses. Flat, striated, or raised ribs are common designs in vertical panels.

Standing Seam Panels Accessories

Steel and Stud offers a comprehensive catalog of accessories and components for your architectural standing seam metal roof and wall projects. We have hand-selected top brands and accessory makers to stock at all important locations in the United States.

Lock strip

Your standing seam metal panels are protected using lock strips, preventing them from losing in the wind or during severe thunderstorms. They’ll be placed at the lower part of your roof or the eaves and rakes.

Clips

Your standing seam metal roof’s clips are what hold the metal panels of your roof together. These clips are put on the male portion of the seam every 12 to 24 inches. They can also be attached to different standing seam metal roof fasteners.

Z bar

A Z-shaped piece of metal is constructed from various standing seam metal roof mesh. This metal flashing needs to be added after the panels are in place to cover the gaps in your roof’s ribs and ridge.

Ridge capping or transition metal

Ridge capping is the trim affixed to a roof’s peak where the two slopes converge. The metal cap will be the same kind and shade as the metal panels on your standing seam metal roof.

Pay Attention to The Flashing details

Several types of standing seam metal roof flashing details are joined at the definite points of the metal roofing system to lock the roof and stop the water flow from the roof. Each component of the metal roofing system is closed using one of a few primary forms of flashing or trim.

The ridge cap is the first flashing detail you need to be aware of. The standing seam panels are strengthened and sealed with the ridge cap. Due to their positioning, ridge caps are crucial because they prevent water from entering while also acting as a barrier against pests.

Best Quality Standing Seam roof in US

Nobody desires a leaking roof. More often than not, leaks might harm other priceless goods in your sweet home, costing more the servicing for the roof. The following are typical uncontrollable triggering circumstances or causes that could result in different types of standing seam metal roof leaks:

- Driving rain

- Heavy or melting snow

- Ice damming (consistent freezing and thawing)

- Wind

- Structural damage

- Other weather occurrences

When you order standing seam metal roofs from Steel and Stud, they will surely last longer than shingles. A four-way interlocking mechanism is frequently used on all sides of the panel for stamped metal roofing, which is subsequently put in staggered courses.

Frequently Asked Questions

It is more efficient than standard metal roof panels. Standing seam profiles has concealed fasteners which eliminates the risk of leaks. You can check out the types of profiles on the steel and studs website.

Whether the panel is directly affixed to the decking material beneath the vertical leg or is linked to the roof deck using a clip, the basic notion of standing seam systems is that the fastener is hidden (fastener flange). You can also try rafters and trusses while building your metal roof.

Avoid the laps and ribs and move as near the decking as possible. Stay as far away from the edge of any decking you’re walking on as possible to prevent having your foot inadvertently get stuck between two boards. Choosing a proper and sustainable foundation for your building is essential to stand correctly on a metal roof.

You should expect your new standing seam metal roof to last at least many years if it is constructed correctly and your attic is properly vented. Steel and Stud are the town’s best standing seam metal roof providers.

Different standing seam roof price ranges exist. The price of a standing seam metal roof varies from $18,000 to $40,000, with a $29,000 national average. The typical price range for labor and materials is $675 to $1,800 per square foot. Steel and Stud provides you with the best metal roof in the town

Standing seam metal roofing, seam metal roofing, or standing seam systems: whichever name you call it: generally face the problem of roll forming panels and coil cutting.

Also, thermal expansion poses a small issue in standing seam metal panels.

The buyers sometimes have difficulty properly handling the mechanically seamed exposed fasteners or standing seam panels.

Standing seam roofing is tightly held by lock strips attached to the roof edges. This arrangement forbids the seam metal roofing from aggressively shaking from the wind. Generally, the mechanical lock panel strips are joined at the bottom edge of the seam metal roofing along with the slanting edge of the standing seam panel.

Indoor Riding Arenas: Types, Features, Benefits, and Cost

Different Types of Metal Roofing for Commercial and Residential Buildings

What Is A Purlin? Types, Sizes, Designs, Accessories & Cost