Red Iron Building

- Kunal Singh

Red Iron is not really iron but instead, it refers to the already manufactured steel which has been colored or sprayed with red iron oxide. Although by extension the color can be used for aesthetics, it is primarily sprayed for protecting the steel from corrosion and damage caused by water. In the construction industry, steel is the most common type of metal used. Besides, it is the most recycled construction material which makes it an eco-friendly option for use during construction.

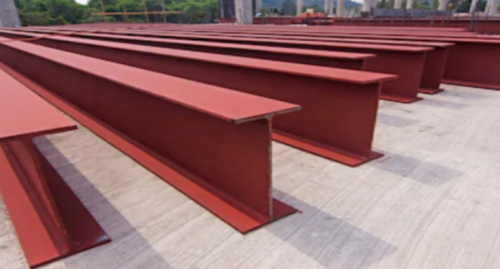

Red Iron Steel

Structures made from steel are cost friendly and can be built very fast. Its uses in construction can be found in a wide range that includes; coastal defenses, deck plates, educational buildings, metal buildings and metal homes, commercial buildings, security, hospitals, skyscrapers, stadiums, industrial buildings, storage buildings, manufacturing plants among other structures.

The Red Iron Buildings

Red Iron Steel Building

The red iron buildings are steel buildings constructed from industrial-grade steel which is primed with a red-tinted iron oxide coat, in a mixture of other alloys. The mixture gives the steel quite an advantage over snow loads and rain as it creates a water-wicking barrier, ultimately protecting the steel from rust and corrosion. The steel buildings are constructed with heavy steel beams.

Heavy Steel Beams

The strength and make-up of the steel allows for a clear span structures. This means that the beams evenly support the weight of the steel building and also manages to carry the load in such a way that there is absolutely no need for interior columns. This disregard of interior columns results to a very spacious building with usable clear-span space.

The I-Beam

In the construction of the red iron steel buildings, the I-Beam is commonly used. I-beams are commonly referred to that way to refer to their capital ‘I’ nature. In structural steel construction, the steel I-Beams have a wide variety of uses. They can be used in the main framework, or as critical support trusses. Whichever use they are put into, they ensure that the structure achieves relentless support and strength which ultimately reduces the need to have numerous structures for support. This gives more structural space, thus cost savings on resources – money and time, and also gives the structure enhanced stability. The I-beams are very ideal for builders because of their versatile and dependable characteristics. While standing horizontally or as columns, the I-beams provide big load-bearing support. The shape of an I-beam ensures that it has limited unidirectional bending that is parallel to the web. For horizontal flanges, they are quite resistant to the bending movement while the shear stress is remarkably resisted by the web.

In making the I-beam, steel is rolled or milled which means that often, the milling equipment determines the size or capacity of the I-Beams. The beams are therefore custom-made into different sizes, section depths, web thickness, weights and flange widths. This makes it easy for buyers when order them since they are classified according to their dimensions and material. For instance, ordering an 11×20 I-Beam is a beam that has a depth of 11inches and weighs 20 pounds per foot. The choice of an I-Beam – its size, depth and weight – is determined by the specific needs of the red iron steel building.

While choosing an I-Beam in the construction of a steel building, a number of factors must be taken into consideration:

- The web thickness must be critically considered so that the I-Beam selected does not buckle, fail or ripple under tension.

- The selection of the flanges is well thought to avoid buckling sideways, locally or torsion-ally.

- The buyer will select a thickness that will reduce the deformation of the beam.

- A particular mass and stiffness are chosen to avoid vibrations inside the building.

- Yield stress should be accommodated easily by the I-Beam’s cross-sectional strength.

The Foundation

Just like any other building, red iron steel buildings require a professionally-made foundation, to ensure that the type of building coming up is strong and well anchored. Before the foundation is made, a professional survey of the land must be done to ascertain that the ground is level and that the exact boundaries of the plot are determined correctly. Grading is then done to ensure that the land’s shape and height conforms to one another.

After the building site has been levelled, excavation for the foundation begins. At this point, it is advisable to consult a with your salesperson or steel buildings manufacturer to get guidelines on what type of excavation will be needed for your red iron steel building’s foundation. Excavations depend on how big the building is; simple steel buildings will need just a minor excavation while bigger buildings will require much deeper excavations.

Several types of foundations can be used which include:

Slab foundation

This type of foundation is comprised of reinforced and poured concrete. This concrete serves as; one, the base where the building is erected upon and two, as the floor that can be used for the interior of the building. However, for the perimeter of the slab and other areas of the building that will require heavy bearing of the walls will be excavated deeper to create room for the footings that give stability to the building. Generally, a slab’s thickness is between 3-1/2” and 5-1/2”.

Perimeter Foundation

Perimeter foundation is different from a slab – foundation. For this type of foundation, only the perimeter that is poured with reinforced concrete. The perimeter wall is composed of the weight-bearing footings. It also goes some inches above the grade and offers a base used for the outside walls of the building that will be erected upon. Depending on the preferences of the owner and the lay of the land, a “ribbon” foundation may be included where an area inside the curb is excavated out to offer a crawl space below.

Floating Slab

This is a combination of a slab and a curb foundation. This type of foundation is commonly used in constructions today. If the building is being set upon on a flat surface, the first step involved is to pour a curb with footings. While the curb is curing and settling, a slab is then poured in the curb. The slab will serve as the floor when the building is finally completed. A good installation of the floating slab reduces the amount of cracking.

Pier foundation

A pier foundation depends on the individual piers (footings) for the steel building’s resting. Usually, the piers are formed from a reinforced concrete that is set deep into the ground below the grade. The depth must be at a point of undisturbed earth or hardpan. Although this is not very welcome for large buildings, they are quite sufficient for smaller structures.

Government rules and regulations

Government is mandated to regulate and maintain standards of building and construction. Several government organizations are tasked with ensuring that certain rules and regulations that govern the construction sector are followed by engineers, contractors, architects among other persons involved in construction.

One of such government organizations is the Occupational Safety and Health Administration (OSHA). Other institutions are the state-based Departments of Consumer Affairs that give guidelines which should be followed for setting up and construction of concrete slabs. Safety guidelines are also availed by these departments that labourers should follow during laying of the foundation and generally, during the construction of the steel buildings. Some of the guidelines associated with construction include:

1. Employees should be provided with respirators when working with concrete.

Sometimes, the dust fumes may be too much and thus, employees need to be protected from it. In addition, a preliminary exam on the employees may be necessitated to assess that every employee is fit to put on a respirator. If a respirator is not necessary at any point, and that employees feel the need to have one, they are allowed to carry one at the construction site. The respirators must also be checked to be in good use.

2. Appropriate face and eye safety clothing

While working at the construction site, it is important to note that all employees must be facilitated with appropriate face and eye safety clothing. After every use, the safety wear must be disinfected. For individuals doing the welding and those that need vision correcting glasses, special provisions must be made to them too. Other protective garments include boots, helmet, insulating gloves among others that will protect the workers from falling debris and electricity shock.

3. Briefing or training employees on accidents and incidents

A very important factor to consider is ensuring that employees are briefed or trained on accidents and incidents that may occur during the construction of the steel buildings. The employer is responsible for that and also for conducting safety inspections. Besides, they mut ensure that all hazardous and potentially risky machinery are well documented by having them labelled appropriately. The machinery should also be inspected and identified correctly.

4. Professional, Full-time personnel supervising the site

Other guidelines dictate that there should be special full-time personnel at the construction site who is responsible for supervising the construction works, site equipment and must be professionally trained with certificates for special works. Also, operations at the safety facilities must be conducted by professionals as guided by the regulations.

In the steel structure construction, holding safety meetings between workers before the next shift is very important. A good handover, communication of precautions and work management, control and prevention of accidents and regular safety persistence must be reviewed and communicated before another shift comes in.

Red Iron Building Kits

Red iron buildings are primarily constructed from red iron which is steel painted or sprayed with red iron oxide. The painting is done to protect the steel from rusting and other corrosive effects. The red iron beams which are known as I-beams -due to their capital I-like appearance – are used in construction of the red iron building. The I-beams do not need columns or support posts. They are capable of holding together the weight from one end to the other, thus leaving the interior spacious. Red iron steel buildings are sturdier than wood-based buildings. The steel buildings are also safe from snow and rain since its red iron oxide forms a protection against water and snow.

The use of red iron oxide promotes environmental conservation since trees are not used for construction of the building. At least 60 trees are used to make frames only in a construction that uses wood. This number of trees cut down would even go higher for enormous buildings like manufacturing plants. However, the use of steel as in red iron ensures zero (0) trees are used hence environmentally friendly.

Uses of Red Iron Structures: Where are they used?

Red iron steel structures, either the prefabricated ones or the ones built from scratch on the ground, just like any other custom building can be used in a variety of ways. These buildings can be used as: coastal defences, deck plates, educational buildings, metal garages and metal homes, commercial buildings, hospitals, skyscrapers, stadiums, industrial buildings, storage building, manufacturing plants, retail shops, riding arenas, farms, garages, among others. The uses of the red iron buildings are only limited to the owner’s imagination. Just like the freedom that one has to use a particular space, for whichever reasons they may want to use it for, so is the unlimited nature of red iron buildings.

The pre-engineered buildings can be customised to fit in the design and style building of the owner. Since the uses differ, the red iron steel buildings may also differ in their construction style, where some may be taller than others, airtight, longer than others, access to sunlight, darker or brighter, etc. Engineers or professionals in the building sector will have to determine the use of the building first thus coming up with the correct type of building package, whose building characteristics refer and apply to the exact needs for its purpose or use.

For instance, a red iron building used for office space will need windows that will allow for easy access to natural light, and air flow. Storage facilities, especially for foodstuff will require an airtight building which can have or become a cold room. Manufacturing plants, aircraft hangars and airplane hangars will require a building whose height is taller than other buildings to accommodate the needed height space. Aircraft hangars, airplane hangars and garages will also require large doors than office space red iron buildings.

Is Red Iron Right for me?

Determining whether red iron is the best-suited material to construct your building depends on a number of factors. Consultations and professional opinions made especially by engineers and architects are the most vital considerations to make. Some of the factors to consider before making the decision to use red iron include:

1. Your budget

Considering your budget is among most important preliminary assessments that you should do. Consult an engineer and an architect to determine the projected cost for the construction of the red iron building. Compare the cost of using red iron versus using wood.

2. The size of your property

This is another important factor to consider. Large properties will be ideal for the red iron steel building. Other prefabricated or pre engineered steel structures can be used for smaller plots or spaces.

3. How much time do you have for building your structure?

Emergency needs calls for emergency responses where most of them are temporally. A permanent solution will call for a more permanent building like the red iron steel building. How much time one has affects greatly the choice of a building to erect.

4. Pay for extra insulation

Red iron steel is already protected from snow and water. Use of other materials like iron will call for painting which is an extra cost. If you have the ability to pay up for the extra cost of insulating the material used, then another choice other than red iron can be made.

Therefore, the decision on whether red iron is the right material for your building is one that will have you consider many project factors. If all the factors do not add up, have a priority list and go for those that are top priority. Consult a professional for them to give you insights and opinions that you will use in coming up with the final decision.

Steps to Buying a Red Iron Building

The following steps are very important and necessary to follow in the purchase of a red iron building.

Step 1: Consider the size

Determine the dimensions that best apply to your intended use. The length, the width and the height. You can find affordable 30×60 Metal Buildings for Commercial and Residential. Therefore, you must be aware of where you want the iron structures to be used.

Step 2: Zoning and permitting

In this step, draw on piece of paper an overview of the property. Then, inside the drawn building draw other structure that relate to the building. Present this piece of paper to the local zoning and permitting departments.

Step 3: The third step is building options

In this step, determine whether the following are needed in your building. The gutters, downspouts, insulation, walk doors, garage doors, windows store front doors, transparent roofing, and other building options. Where possible, engage the salesperson or construction professionals in determining this

Step 4: Pricing

After determining the building options, you should be provided with a quotation that entails the options you have provided. The quotation should also include the shipping fee, unless it is completely free to ship the materials. Depending on the company where you buy the materials / building, you will pay a percentage as the down payment. You should then be provided with certified wet stamped drawings for the materials to be used for construction of the building. Also, you should receive comments and reactions especially on the transfer of weight to the concrete by the columns. Also included should be the specific drawings of the anchor bolts.

Take the engineering drawings that you are provided with to the zoning departments. The persons at the department will then determine whether you need a foundation engineer or a foundation contractor to get your building’s concrete plans ready. This will depend with the local zoning laws in the area where the construction site is.

Step 5: Concrete

After you have ordered the building, and finished with the previous steps, then engage the foundation engineer or foundation contractor who will first put the foundation into drawing, basing on the building drawings, and the reactions and plans on the anchor bolts. Based on the drawings and the guidance of the contractor or engineer, the labour work begins.

Step 6: Delivery

After making the order for the building and the pouring of concrete is done, the building will arrive within 4 days to 7 days. The building materials, (red iron steel) will be lifted using special machinery, either the forklift or the telescoping lift. It is advisable to schedule the delivery time with the installation time, so as to use the lift all at once.

Step 7: Installation

The installation works can be purely done by a contracted company or you can do the installation by yourself if the building is not big.

How does the Red Iron building go up?

The following eight steps detail how the red iron steel buildings go up.

- The pouring of the foundation and the positioning of the anchor bolts is done, in accordance to the recommendations of the blueprint.

- Erection of the columns all the way from the anchor bolts with the nuts and the washers is one. Advisably, take enough time and work in precision.

- Installation of the side wall girts, eave struts, purlins and rafters that will complete the framing.

- Step four is getting the bracing installed that will avoid wind sway from interfering with the structure before the base trim is installed.

- Drilling of the wall sheets into the steel frame.

- Adding insulation to the walls that control temperature and prevent pests from destroying the building.

- Installation of the roof sheet and roof insulation.

- Installation of the trim as the finishing step.

The exact times and process will be determined by the complexity of the customized steel building. For instance, some buildings have installation of solar panels, skylights, exterior painting and roll-up doors.

Advantages and disadvantages of using red iron steel

Why do many people prefer using red iron?

- Steel, by its composition, is comprised of 77% of recyclable material.

- When recycled, steel does not lose its durability or strength, thus maintaining its competitive properties.

- Use of steel ultimately contributes to environmental conservation since, many wooden buildings, by time of completion require more than 60 trees to construct the frames only. However, use of steel saves the need to use trees which makes it environmentally friendly.

- Due its make-up, red iron steel is quite resistant to termites and rodents, fire and also rust. It can therefore be dug in the ground, or used in surfaces that have water without fear of destruction or being “eaten away” by rust.

- Over time, steel has maintained a cheaper end result as compared to when one is using wood.

- The red iron’s I-beams are strong which ensures that the end result is a sturdier steel building and will not need a lot of load-bearing columns.

The use of steel in construction reduces cost of construction by a huge margin. It also ensures that the steel buildings are strong and free from destruction. The non-corrosive and non-destructive nature of the red iron steel buildings makes long lasting as compared to other construction materials like wood and iron

However, the use of red iron may be limited by a number of factors which are in the qualities of the red iron. They are:

- Red iron is fragile to cold or heat. This is attributed to the fact that red iron is a good conductor.

- Installation of red iron may be costly.

- Red iron building are more favorable for bigger structures like factories, agricultural buildings, manufacturing plants, farm equipment storage and large vehicle storage.

- Setting up the red iron building will require the assistance of professionals; therefore, one cannot do by themselves.

Conclusion

Making a decision to install a steel structure must be very informed. It requires a lot of consultation and professional guidance, which cannot be gotten just from any personnel. Qualified and certified professionals such as Steel and stud are the best to work with. This also involves the purchase and installation of the building. Remember to always buy materials that are certified and from a certified seller. We at Steelandstud offer quality consultation services and also sell certified red iron steel and other steel materials.

Indoor Riding Arenas: Types, Features, Benefits, and Cost

Different Types of Metal Roofing for Commercial and Residential Buildings

What Is A Purlin? Types, Sizes, Designs, Accessories & Cost